Commercial wall packs are easy to spot—they’re used on essentially every industrial facility, warehouse, college campus, retail facility, and hospital around the United States and beyond. While new wall pack styles and designs become available every year, one question remains unchanged: Which is the best material for outdoor lights? Is it better to select glass or polycarbonate outdoor lights?

Both glass and polycarbonate outdoor lights look similar, so this is less a matter of aesthetics than something like, say, choosing bronze or black housings. The factors that will be important include resistance to scratches, cracks, and shatters; glare resistance; weight; and ease of installation and replacement. Additionally, considering durable materials is crucial for ensuring longevity and minimal maintenance. Using weather resistant material like brass, glass, and aluminum can help these fixtures withstand harsh weather conditions while maintaining their aesthetic and functional qualities over time.

Choosing the Right Outdoor Lighting Material

When it comes to selecting the perfect outdoor lighting material, there are several factors to consider. The right material can make all the difference in ensuring that your outdoor lighting fixtures withstand the elements and provide the desired ambiance for your outdoor space.

Consider the durability and weather resistance of the material

One of the most important factors to consider when choosing an outdoor lighting material is its durability and weather resistance. You want a material that can withstand harsh weather conditions, such as heavy rain, intense sunlight, and extreme temperatures. Materials like stainless steel, brass, and copper are excellent choices for outdoor lighting fixtures due to their corrosion resistance and ability to withstand harsh weather conditions. These materials are known for their longevity and can maintain their appearance and functionality even in the most challenging outdoor environments.

Think about the style and design of your outdoor space

The style and design of your outdoor space should also play a significant role in your material selection. For example, if you have a modern and sleek outdoor space, you may want to consider materials like glass or aluminum that can provide a clean and minimalist look. On the other hand, if you have a more traditional or rustic outdoor space, materials like copper or bronze may be a better fit. These materials can add a touch of elegance and timelessness to your outdoor lighting design, enhancing the overall aesthetic of your space.

Ensure the material is suitable for your climate and environment

It’s also important to consider the climate and environment in which your outdoor lighting fixtures will be installed. For example, if you live in a coastal area, you may want to choose materials that are resistant to saltwater corrosion, such as stainless steel or brass. Similarly, if you live in an area with high winds, you may want to choose materials that are sturdy and can withstand strong gusts. Selecting the right material for your specific climate and environment will ensure that your outdoor lighting fixtures remain functional and attractive for years to come.

Borosilicate Glass and Polycarbonate Lensing in Outdoor Lighting: A Brief History

Borosilicate glass predates the discovery of polycarbonate and is used in many applications within and beyond the lighting industry. Borosilicate glass was first available in 1893 and was launched by the company now known as SCHOTT AG under the brand name DURAN®. It was originally designed as laboratory glassware and was preferred over other options for its durability and chemical resistance. In 1915, Corning Glass Works began producing an improved version, Pyrex, which is often seen as synonymous with borosilicate glass.

Many lighting manufacturers use borosilicate glass for wall packs, bollard lights, flood lights, and walkway lights. Prismatic borosilicate glass is popular for its durability and its added glare protection.

First discovered at the turn of the 20th century, polycarbonate would remain in development for nearly fifty years before the first products ventured out into the open market. Thanks to Bayer in Germany and General Electric in the United States, polycarbonate items eventually began to populate the marketplace; the first iterations of polycarbonate actually had a brown hue. It wasn’t until the 1970s that clear polycarbonate lenses came into production. Now, polycarbonate is a popular material used for electrical applications, light fixtures, beverage cans, and more.

Pros and Cons: Glass Outdoor Lights

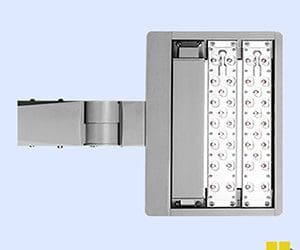

Pictured is the 25w HEZE Turtle & Wildlife Friendly Wall Pack, which is small, lightweight, and equipped with a clear flat glass lens. It offers a tremendous 196,000-hour lifetime (L70). Shop the HEZE by clicking the image above.

Pictured is the 25w HEZE Turtle & Wildlife Friendly Wall Pack, which is small, lightweight, and equipped with a clear flat glass lens. It offers a tremendous 196,000-hour lifetime (L70). Shop the HEZE by clicking the image above.

Glass has the advantage of having been around for a few centuries and having gone through numerous advances, innovations, and evolutions. The primary advantage to glass is its resistance to scratching. While glass can certainly still be scratched, it is inherently much more difficult to scratch than polycarbonate. The added scratch resistance of glass is certainly attractive, as it protects the fixtures from small debris and damage from the elements.

Additionally, glass is still one of the most optically clear materials available. This is why it is still the material of choice for many tools outside of the lighting industry, including camera lenses, binoculars, and microscopes. Brass fixtures are another durable and corrosion-resistant option for outdoor lighting, especially in coastal areas. They develop a patina over time, adding to their aesthetic appeal, and although they come with a higher price, their longevity and classic look make them a worthwhile investment for quality lighting solutions.

While glass has its advantages, the drawbacks are just as glaring (no pun intended). While glass may be resistant against scratches, it has minimal impact resistance; it can easily be cracked or broken altogether. Because wall packs are often installed well above eye level, it may not be evident when a unit has broken glass. The longer a wall pack remains damaged, the more susceptible its internal components are to water damage. Of course, there is also the issue of broken glass on the ground beneath the unit—if the wall pack is installed over a playground, sidewalk, or another trafficked location, there is the potential for injury during or after a break. Older wall packs not using LEDs often use light sources containing mercury, which further amplifies the risk of injury.

The relative delicacy of fixtures with glass lenses makes it easy for fixtures to be broken during transit or installation. Even the most safely packed glass fixtures run the risk of breakage. Replacing units quickly becomes a timely and financial inconvenience and often requires rescheduling of electricians, etc. Glass is much heavier than polycarbonate (it weighs about twice as much), so shipping glass outdoor lights will be more expensive than shipping polycarbonate outdoor lights; handling these heavier units also complicates installation and handling.

Another factor in the glass vs. polycarbonate debate is yellowing. This is most often an issue with older (pre-LED) lighting technologies, but glass has proven to last longer before fading or turning yellow. Glass may be better protected against scratching, but polycarbonate does often turn yellow after years of use.

Pros: stylish, easy to clean, and can be energy-efficient

Outdoor lighting materials like glass, aluminum, and stainless steel offer several benefits, including being stylish, easy to clean, and energy-efficient. Glass, for example, can provide a sleek and modern look, while also being easy to clean and maintain. Aluminum and stainless steel, on the other hand, are durable and can withstand harsh weather conditions, making them ideal for outdoor use. These materials can also contribute to energy efficiency, as they often support modern LED lighting technologies that consume less power and have a longer lifespan.

Cons: may be prone to breakage, can be expensive

However, some outdoor lighting materials may have some drawbacks. For example, glass can be prone to breakage, especially if it’s exposed to extreme weather conditions. Additionally, some materials like copper and bronze can be expensive, especially if you’re looking for high-quality fixtures. It’s important to weigh these potential downsides against the benefits to determine the best material for your outdoor lighting project.

By considering these factors and weighing the pros and cons of different materials, you can choose the perfect outdoor lighting material for your outdoor space. Whether you’re looking for durability, style, or energy efficiency, there’s a material out there that can meet your needs and provide the perfect ambiance for your outdoor space.

Pros and Cons: Polycarbonate Outdoor Lights

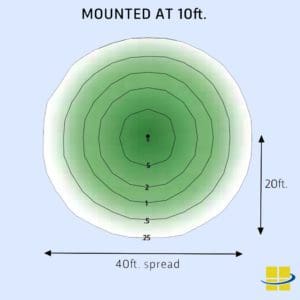

Pictured are the photometrics for the 20w ANDO Vandal Resistant LED Garage-Canopy Light. This fixture uses a prismatic, polycarbonate lens and, when mounted at 10 feet, provides distribution to a 40 ‘ x 40’ area. Shop the ANDO by clicking the image above.

Pictured are the photometrics for the 20w ANDO Vandal Resistant LED Garage-Canopy Light. This fixture uses a prismatic, polycarbonate lens and, when mounted at 10 feet, provides distribution to a 40 ‘ x 40’ area. Shop the ANDO by clicking the image above.

Compared to glass, polycarbonate is a relatively new option. It has not seen as dynamic an evolution as glass, but that has not stopped it from becoming a strong force in the lighting marketplace. The biggest claim to fame for polycarbonate is that it is highly resistant to impact; depending on the composition, polycarbonate can be up to thirty times more resistant to breakage than glass.

Other advantages is that polycarbonate is that it is lighter in weight than glass and is often easier to remove and replace than glass. Glass rarely breaks cleanly, so part of the replacement process generally involves picking out shards of glass where they don’t belong. Polycarbonate, however, can usually be removed and replaced in one piece.

Polycarbonate is also weather resistant, making it suitable for outdoor lighting applications. The flexibility of polycarbonate makes it easier for manufacturers to produce customized lens designs for new products. Glass lenses can be custom designed as well, but that process can be expensive and put to risk the strength of the glass itself. Polycarbonate allows manufacturers to take advantage of the material’s flexibility and low production cost. Thanks to its strength properties, polycarbonate can be shaped and reconfigured through a thermoforming process.

For all of the advantages polycarbonate offers in terms of durability, there is one major detraction: scratches. Where glass is scratch resistant, polycarbonate is quite easily affected by scratches. Often, manufacturers will add an acrylic coating to a polycarbonate lens to improve its scratch resistance, though the risk is still present. This coating can also negatively affect a polycarbonate wall pack’s ability to absorb impact and make it more vulnerable to chips, cracks, and breakage.

The strength of polycarbonate is largely dependent on its thickness. So, while ⅛” of polycarbonate may be more shatter-resistant than ⅛” of glass, some manufacturers may cut costs by using thinner polycarbonate.

Borosilicate Glass vs. Polycarbonate Outdoor Lights: The Verdict

The choice is up to you. For increased scratch resistance, optimal optical clarity, and a lesser likelihood of yellowing, choose glass. When considering outdoor elements, it’s important to note that stainless steel is designed to withstand corrosion caused by these conditions. For increased breakage resistance, less weight, easier maintenance, and additional flexibility, choose polycarbonate.

Speak to an Access Fixtures Lighting Specialist

Lens material is just one factor to consider when selecting wall packs—and, while it is important, we do not recommend selecting a wall pack on this data point alone. Access Fixtures has a team of lighting specialists on standby to help you select the exact glass or polycarbonate outdoor lights for your specific project, including outdoor spaces. Accent lighting can dramatically enhance the aesthetics of these areas by highlighting architectural features. Call us today at 800-468-9925 or reach us via email at [email protected] today.