When comparing LED vs induction lamp, or even ceramic metal halide (CMH) and light-emitting plasma, their efficiency, lifespan, cost, and applications matter. This is a guide that explains each of these lighting technologies, and why LED consistently comes out at the top of the list

Key Takeaways

-

- LED lighting surpasses induction lamps, ceramic metal halide, and light-emitting plasma due to its superior energy efficiency, longevity, and versatility.

- In the LED vs induction lamp debate, induction excels in durability and low maintenance, ideal for hard-to-reach spots, but lacks light control.

- Cost analysis reveals that while LEDs have a higher upfront cost than induction lamps, their energy savings and reduced maintenance make them more cost-effective long-term.

Understanding LED and Induction Lighting

LED lighting represents a significant milestone in lighting technology. Unlike traditional incandescent lamps that rely on gas or filaments, LEDs (light emitting diode) utilize semiconductor technology to produce light, making them incredibly energy-efficient and versatile. In the LED vs induction lamp comparison, LEDs shine with customizable color temperatures (2200K to 5700K), high CRI (70+ to 90+), and superior optical control via over 20 beam angles (e.g., 10°, 25°, 40°, 60°, 90°, 120°, 150°, Type II-V distributions). This makes LED technology ideal for a wide range of applications, from residential to commercial and industrial settings.

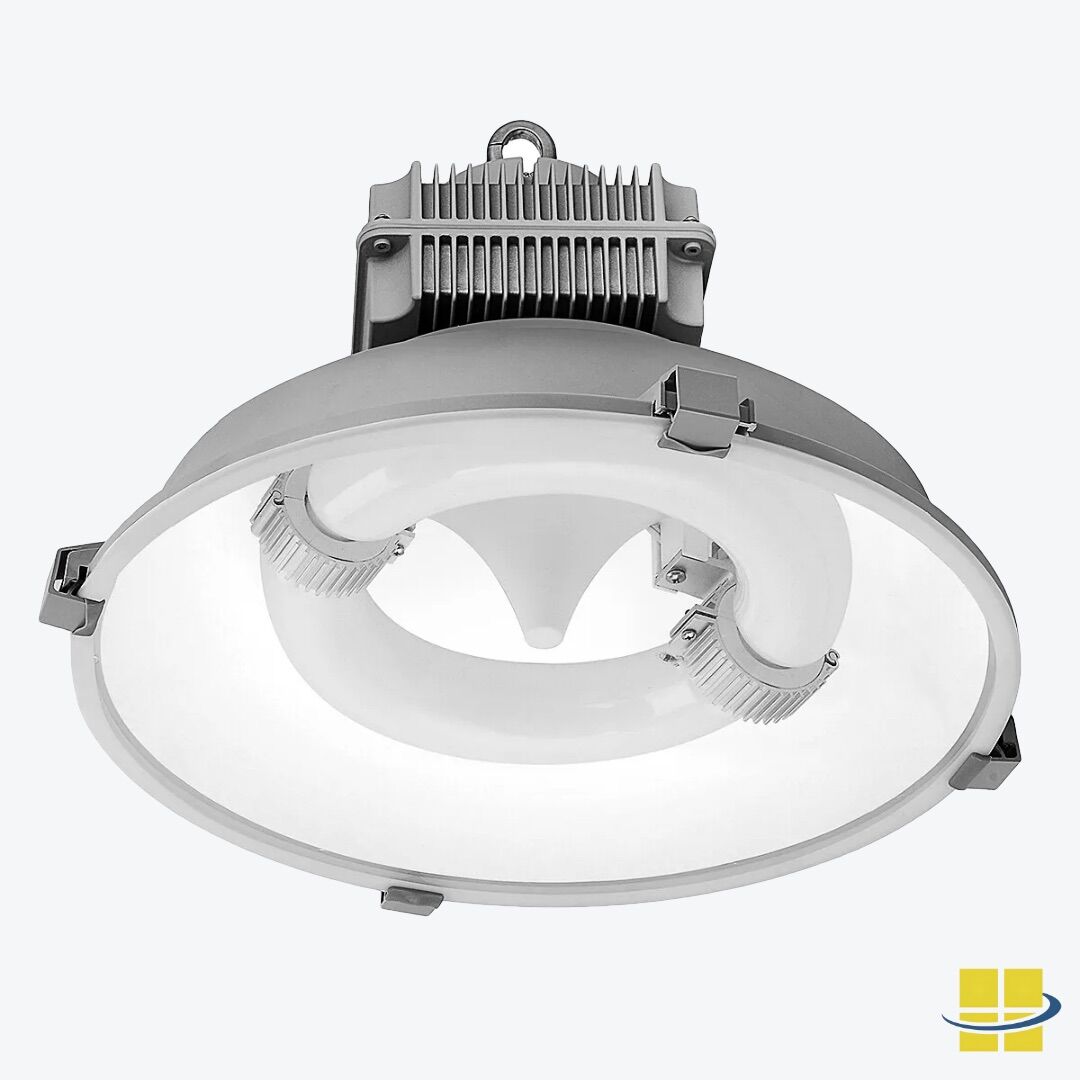

On the other hand, induction lighting operates similarly to a fluorescent lamp by using an electromagnetic pulse to excite a mixture of gases. Induction lamps are known for their durability, as they employ an externally situated electromagnet, which enhances their longevity compared to fluorescent lights.

Induction lighting is often favored in scenarios where minimizing maintenance is crucial, such as in hard-to-reach areas or locations requiring continuous illumination. The choice between induction lighting versus LED and induction lighting should be based on the specific requirements of the space and the activities conducted there.

Understanding Light-Emitting Plasma Lighting Technology

Light-emitting plasma technology once held great promise in the lighting industry. It generates light from a capsule no larger than a grain of rice, making it incredibly compact. With fixtures capable of producing up to 32,000 lumens at 320 watts, the potential for bright and efficient lighting seemed boundless. This technology was even utilized by Access Fixtures to illuminate tennis courts, showcasing its impressive capabilities.

However, despite its initial success, light-emitting plasma faced significant challenges. The technology was limited by its wattage per fixture and high costs, just as LED lighting was rapidly evolving.

LEDs began to match and even surpass the lumen output of light-emitting plasma, making them a more practical and cost-effective option for many applications. As a result, light-emitting plasma gradually fell out of favor, overshadowed by the advancements in LED technology.

Understanding Induction Lighting

Induction lighting stands out for its remarkable longevity and minimal maintenance requirements. Unlike traditional lamps, induction lamps do not have cathodes inside, allowing them to operate for hundreds of thousands of hours without burning out. This makes induction lighting an excellent choice for locations that are difficult to access or where continuous operation is essential, such as in nuclear power plants or high-traffic areas like escalators.

Despite its long lifespan, induction lighting does have limitations. One of the primary drawbacks is its inability to focus or project light effectively. The light emitted by induction lamps cannot be easily controlled by optics, which restricts their applications to scenarios where broad, unfocused illumination is acceptable.

Nevertheless, the reliability and durability of induction lighting make it a valuable option in specific contexts.

Understanding Ceramic Metal Halide (CMH)

Ceramic metal halide (CMH) lighting paved the way for significant energy savings and improved color rendering. Transitioning from a 100-watt PAR38 halogen lamp to a 27-watt PAR38 CMH lamp cut energy use by 73% and extended lamp life tenfold. This made CMH an attractive option for retail lighting, where both energy efficiency and high color rendering are critical.

However, the high cost of CMH lamps posed a significant barrier to widespread adoption. As LED technology continued to advance, it became apparent that LEDs would eventually surpass CMH in performance and do so at a lower cost. This shift in the market led to a decline in the popularity of CMH lamps, as more industries and consumers began to favor the versatile and cost-effective solutions offered by LED lighting.

Why LED Lighting Beat Induction, Ceramic Metal Halide, and Light-Emitting Plasma Lighting Technology?

CMH, light-emitting plasma, induction, and LED each outperformed legacy technologies like fluorescent and halogen, but LED won. In LED vs induction lamp, LED offers:

- Longevity: From L70 @ 50,000 hours to EXTREME-LIFE 600,000+ hours, outlasting induction’s hundreds of thousands.

- Energy Efficiency: Up to 160 lumens per watt vs induction’s 90.

- Versatility: Kelvin options (2200K-5700K), high CRI (70-90+), and direct light with advanced optics.

- Control: Superior to induction’s uncontrollable 360° output.

LED’s evolution began with bulbs, proving viable in fixtures like MR16s or GU11s with low energy use and great optics. Early commercial LED fixtures faced condensation issues in traditional housings—unlike metal halide, LED didn’t burn off moisture, causing failures. Access Fixtures, likely the first to light a tennis court with LED, saw this firsthand. Engineers added weep holes and waterproofed components, creating durable replacements that lasted over a decade. Improved boards, housings, and optics followed, setting L70 @ 50,000 hours as standard and EXTREME-LIFE fixtures (e.g., APTA at 200,000 hours) as the peak, phasing out induction, CMH, and plasma.

LED now splits into closed-in fixtures (traditional form, L70 50,000-600,000+ hours, control-ready) and modular open-architecture designs (e.g., CARO at 50,000 hours, APTA at 200,000 hours). Open designs use waterproof modules, no glass, and superior heat dissipation, cutting costs and boosting durability. These advancements have made obsolete other technologies like light-emitting plasma, induction, and ceramic metal halide.

| Feature | LED | Induction Lamp | Ceramic Metal Halide (CMH) | Light-Emitting Plasma |

|---|---|---|---|---|

| Energy Efficiency | Up to 160 lumens/watt | ~90 lumens/watt | 80-100 lumens/watt | ~100 lumens/watt |

| Lifespan | L70 @ 50,000–600,000+ hours | Hundreds of thousands of hours | 10x halogen (~20,000 hours) | Decent, but less than LED |

| Maintenance Costs | Low (replaceable modules, e.g., APTA) | Very low (long life, no cathodes) | Moderate (longer than halogen) | Higher (costly replacements) |

| Light Control | Superior (20+ beam angles) | Poor (unfocused 360° output) | Moderate (some control) | Limited (high wattage focus) |

| Color Rendering (CRI) | 70–90+ (customizable) | ~80 | 90+ (excellent) | 70–85 |

| Initial Cost | Higher | Moderate | High | High |

| Applications | Versatile (all settings) | Hard-to-reach areas | Retail (High CRI) | High-intensity |

| Environmental Impact | Low (energy-efficient) | Low (long life, less heat) | Moderate (less efficient) | Higher (high energy use) |

Energy Efficiency Comparison of Induction, Ceramic Metal Halide (CMH) and Light Emitting Plasma Technology

When it comes to energy efficiency, each lighting technology offers distinct benefits. Induction lighting typically saves over 50% in energy consumption compared to traditional lighting, operating at around 90 lumens per watt. Induction lamps also produce less heat, which can reduce cooling costs in certain environments. Additionally, induction lighting is known for its longevity, often lasting up to 100,000 hours, which minimizes maintenance and replacement costs. This makes it particularly suitable for locations that are difficult to access, such as high ceilings or remote areas.

In comparison, LED lighting is even more energy-efficient, achieving levels of up to 120 lumens per watt and reducing energy consumption by over 50% in various applications. LED systems can incorporate smart controls to further enhance energy savings, making them a highly energy-efficient choice for many settings. LEDs are also renowned for their impressive lifespan, often exceeding 200,000 hours, especially with advanced fixtures like the APTA series. Their ability to provide directional light enhances their efficiency in targeted applications. This combination of energy efficiency and longevity makes LED lighting an increasingly popular choice for both residential and commercial

Meanwhile, ceramic metal halide lamps, while offering significant energy savings over halogen lamps, have been surpassed by the efficiency and versatility of LED technology. Ceramic metal halide lamps operate at a lower efficiency compared to LEDs, typically achieving around 80-100 lumens per watt. In contrast, LED lighting can reach up to 120 lumens per watt, making LEDs a more efficient choice for reducing energy consumption. Additionally, LEDs offer advancements such as smart controls and dimming capabilities, further enhancing their energy efficiency. This increased efficiency not only results in lower energy costs but also contributes to a reduced environmental impact. As LED technology continues to advance, its superiority in energy efficiency becomes even more pronounced, solidifying its status as the preferred choice for both residential and commercial lighting applications.

Light Emitting Plasma Technology, while once considered a promising innovation in lighting, falls short in energy efficiency when compared to the advancements of LED lighting. Light-emitting plasma operates at a high wattage to produce bright illumination, but it cannot match the energy efficiency of LEDs. LEDs achieve remarkable energy efficiency, often reaching up to 120 lumens per watt, which significantly reduces energy consumption. In contrast, light-emitting plasma technology, despite its initial potential, struggles to compete with the lower energy usage and superior performance of LED systems.

LED lighting’s integration with smart controls further enhances its energy-saving capabilities, allowing for precise control of light output and reducing unnecessary energy use. This makes LEDs a more energy-efficient choice for a wide range of applications, from residential to commercial and industrial settings. As a result, the shift towards LED technology is driven by its ability to provide substantial energy savings while maintaining high-quality illumination.

In comparison, LED lighting is even more energy-efficient, achieving levels of up to 120 lumens per watt and reducing energy consumption by over 50% in various applications. The use of smart controls with LED systems can further enhance energy savings, making LEDs a highly energy-efficient choice for many settings.

Longevity and Maintenance Costs

Lighting technologies vary widely in terms of longevity and maintenance costs. Induction lighting fixtures can operate for hundreds of thousands of hours without burning out, making them ideal for hard-to-reach locations where maintenance is challenging. This long lifespan significantly reduces the frequency of replacements and associated maintenance costs. Similarly, ceramic metal halide (CMH) lighting, while not as long-lasting as induction lamps, offers a notable improvement over traditional incandescent lamps. CMH lamps provide substantial energy savings and have a longer lamp life, which can reduce maintenance costs in commercial settings.

Light-emitting plasma technology, once a promising innovation, also offered a decent lifespan and maintenance benefits. However, it was eventually overshadowed by the advancements in LED technology, which provided superior longevity and energy efficiency. Although light-emitting plasma fixtures could produce bright illumination, their maintenance requirements and higher energy consumption limited their appeal compared to LEDs. As a result, both CMH and light-emitting plasma technologies have seen a decline in popularity, with LED lighting emerging as the preferred choice due to its exceptional longevity, reduced maintenance costs, and energy efficiency.

LED lighting also offers impressive longevity, typically lasting around 50,000 hours, with some high-end fixtures like the APTA series rated at L70 for up to 200,000 hours. This extended lifespan, combined with lower depreciation rates, makes LEDs a reliable option for emergency lighting and other critical applications. The reduced need for replacements and maintenance translates into significant cost savings over time.

Performance in Different Environments

Different lighting technologies perform variably across diverse environments. LED, induction lamps, ceramic metal halide, and light-emitting plasma lighting are commonly used in industrial settings, outdoor spaces, and emergency applications, each with unique strengths and limitations.

The following subsections delve into their performance in specific contexts.

Industrial Applications

In industrial applications, both LED and induction lights offer durability and energy efficiency. Induction lighting is particularly well-suited for large commercial settings requiring high brightness, as it stays relatively cool even in high-heat environments. For example, replacing metal halide fixtures with induction fixtures at the University of California, Santa Cruz, reduced the fixture count by 60%, improved light distribution, and increased light levels to 35 footcandles.

Ceramic metal halide lamps provide good color rendering and are often used in retail and display settings where visual accuracy is important. However, they can be less energy-efficient and generate more heat, which may require additional cooling measures.

LED lighting, on the other hand, is less affected by temperature fluctuations and can operate effectively in varying weather conditions, making it ideal for both indoor and outdoor industrial applications. Its ability to integrate with smart controls and provide instant-on capabilities further enhances its suitability for industrial settings.

Parking Lots and Outdoor Spaces

When it comes to parking lots and outdoor spaces, temperature tolerance and durability are crucial. Induction lighting handles heat better than many alternatives, making it suitable for environments that experience high ambient temperatures. This reliability ensures consistent performance in outdoor settings where temperature variations can be significant.

LED lighting also excels in outdoor applications due to its resistance to temperature fluctuations and ability to provide instant illumination without warm-up periods. These characteristics make LEDs a popular choice for parking lots, street lighting, and other outdoor spaces where consistent and reliable lighting is essential.

Light-emitting plasma technology, while capable of producing high-intensity light, struggles with energy efficiency in outdoor settings compared to LEDs. Its high wattage requirements and less efficient energy use make it less favorable for large-scale outdoor applications.

Emergency Lighting

Both LED and induction lamps are reliable for emergency lighting, turning on instantly without flicker to ensure immediate illumination when needed. This reliability is crucial in emergency situations where consistent and dependable lighting can make all the difference.

Ceramic metal halide and light-emitting plasma technologies are less commonly used for emergency lighting due to their slower start-up times and higher energy consumption, making them less ideal for scenarios requiring immediate and energy-efficient light sources.

Light Quality and Color Rendering

Light quality and color rendering are critical factors in choosing the right lighting technology. Induction lamps have a Color Rendering Index (CRI) averaging 80, which indicates good color rendering potential. LEDs, however, can achieve CRI values between 70 and 90, offering a broader range of color representation possibilities. This makes LEDs particularly versatile in applications where accurate color rendering is essential.

Ceramic metal halide (CMH) lamps are renowned for their excellent color rendering, with a CRI often exceeding 90. This makes them ideal for applications where visual accuracy and color quality are paramount, such as in retail or display settings. However, they can be less energy-efficient compared to LEDs.

Light-emitting plasma technology, while once promising, typically offers a CRI in the range of 70 to 85. Although it can produce bright and intense illumination, its color rendering capabilities are not as advanced as those of CMH or high-quality LED systems.

Both LED and induction lighting provide a wide range of color temperatures, from warm 2700 Kelvin to cool 6500 Kelvin, allowing for various lighting effects. The ability to select the appropriate color temperature and CRI can significantly impact the ambiance and functionality of a space, making these technologies ideal for diverse applications. CMH lamps also offer a range of color temperatures, but their higher energy consumption can be a drawback. Light-emitting plasma, while versatile, is often overshadowed by the superior efficiency and color rendering of modern LEDs.

Features and Advantages of APTA Fixtures

The Access Fixtures APTA light fixtures are a versatile and high-performance line of LED lighting solutions designed for various applications, including commercial, industrial, sports, and specialty environments.

APTA fixtures represent the pinnacle of LED lighting performance and durability. Rated IP66 and IK10, these fixtures are resistant to harsh weather conditions and impact, making them ideal for challenging environments. They can operate effectively in extreme temperatures, ensuring reliable performance even in the most demanding settings.

Designed with an anti-corrosive marine-grade finish and a surge protection capacity of 10ka, APTA fixtures offer robust protection against environmental factors. Their versatility and high-performance features make them suitable for various applications, from commercial and industrial to sports and specialty environments.

Below is a detailed overview of their key features based on available information:

- APTA fixtures are rated at L70 @ 200,000 hours, meaning they maintain at least 70% of their initial light output after 200,000 hours of operation. This translates to virtually maintenance-free performance over an extended period.

- APTA has Independently driven LED modules (“bricks”) that can be replaced individually if they fail, avoiding the need to swap out the entire unit.

- Depending on the model, APTA fixtures deliver up to 160 lumens per watt, providing energy-efficient illumination.

- Available in a broad range of wattages, from as low as 60 watts to as high as 2400 watts, allowing customization for different lighting needs.

- APTA fixtures offer over 20 beam angle options (e.g., 10°, 25°, 40°, 60°, 90°, 120°, 150°, and various Type II, III, IV, and V distributions), enabling precise light distribution tailored to specific projects.

- APTAs have optic lenses or diffusers to reduce glare, improving visibility and comfort.

- Available in multiple Kelvin options, including 2200K, 3000K, 4000K, 5000K, and 5700K, to suit different ambiance and visibility requirements.

- Standard CRI is 70+, with optional upgrades to 80+ or 90+ for enhanced color accuracy.

- APTA fixtures are IP66 or IP67 rated, offering complete protection against dust and strong water jets (IP66) or temporary submersion (IP67), making them ideal for harsh or wet environments like clean rooms or outdoor settings

- APTAs are IK10 Impact Resistance Rated to withstand up to 20 joules of impact, ensuring vandal-proof durability.

- A marine-grade, corrosion-resistant polyester powder coating and a 1,000-hour salt-spray certification for longevity in challenging conditions.

- Operates effectively in ambient temperatures from -40°C (-40°F) to +50°C (122°F).

- Easily integrates with all controls including dimming, occupancy sensors, microwave motion sensors, DALI, and more for energy savings and customizable operation.

Conclusion

In conclusion, we didn’t wake up one morning and find state-of-the-art LED lighting replaced legacy lighting and other emerging technologies. It was a progression and here’s where we are. The difference between LED, induction, ceramic metal halide, and light-emitting plasma lighting technologies depends on various factors, including energy efficiency, longevity, maintenance costs, and specific application requirements. While each technology has its unique advantages, LED lighting has emerged as the dominant solution due to its versatility, superior performance, and cost-effectiveness. By understanding the strengths and limitations of each option, you can make an informed decision that meets your specific lighting needs and contributes to environmental sustainability. If you want to find a high-performance lighting solution for your facility, speak with an Access Fixtures Lighting Specialist.

Induction, CMH, Light-Emitting Plasma Technology & LED Frequently Asked Questions (FAQs)

You have questions on Induction, ceramic metal halide, and light emitting plasma technology and why LED beat them. We have answers. If you have a question that isn’t answered below, contact an Access Fixtures lighting specialist at (800) 468-9925 or click here.

What are the main advantages of LED lighting over other technologies?

The main advantages of LED lighting are its energy efficiency, extended lifespan, improved color rendering, and versatility, making it superior to other lighting technologies such as induction and ceramic metal halide. Adopting LED lighting can lead to significant long-term benefits for both cost and quality of illumination.

How does induction lighting compare to LED in terms of maintenance costs?

Induction lighting generally has lower maintenance costs due to its longer lifespan and fewer replacements compared to LED lighting. However, both options are reliable and cost-effective over time.

Are APTA fixtures suitable for harsh environmental conditions?

APTA fixtures are indeed suitable for harsh environmental conditions, as they are rated IP66 and IK10 for dust, water, and impact resistance, and can operate effectively in extreme temperatures. This ensures their reliable performance even in challenging situations.

What considerations should be made when choosing between LED and induction lighting for industrial applications?

It is crucial to evaluate energy efficiency, maintenance costs, and temperature tolerance when choosing between LED and induction lighting for industrial applications. LEDs excel in varying temperature conditions, while induction lighting performs well in high-heat environments.

How do LED and induction lighting impact the environment?

LED and induction lighting positively impact the environment by significantly reducing carbon dioxide and greenhouse gas emissions. Their energy efficiency and longevity lead to lower energy consumption, thus minimizing overall environmental effects.