Light Pole Vibration Damper: Application Guidelines

Steel and aluminum poles for LED lighting applications may incur issues from wind-induced light pole vibration. Knowledge of the potentially damaging effects and what to look for can minimize the potentially damaging effects of wind on light poles.

Key Takeaways

-

-

Risk Assessment and Design Considerations: Thorough understanding and integration of design factors such as height, material, and aerodynamics are essential to reduce the risk of wind-induced light pole vibration.

-

Regular Inspections and Maintenance: Implementing a consistent schedule for pole inspections and maintenance can preemptively address potential issues, extending the life and functionality of the light poles.

-

Use of Dampers: Incorporating vibration dampers is a proven strategy to counteract the effects of resonance and harmonic vibrations, thereby ensuring the structural integrity and stability of light poles.

-

Understanding Light Pole Vibration

Light pole vibration refers to the oscillation or swaying of light poles, typically caused by wind. This phenomenon can be attributed to various factors, including the pole’s design, material, and environmental conditions. Understanding light pole vibration is crucial to prevent damage, ensure safety, and maintain the structural integrity of the pole. When wind interacts with a light pole, it can induce vibrations that, if not properly managed, may lead to material fatigue or even structural failure. By comprehending the underlying causes and effects of light pole vibration, stakeholders can implement effective strategies to mitigate these risks and enhance the durability of their lighting installations.

Causes of Light Pole Vibration

Wind is the primary cause of light pole vibration. The wind’s velocity, direction, and turbulence can all contribute to the pole’s oscillation. For instance, high wind speeds can generate significant forces on the pole, leading to increased vibration. Additionally, the pole’s height, material, and shape can also affect its vibration. Taller poles are more susceptible to wind-induced oscillations due to their increased exposure to wind forces. Similarly, certain materials and shapes can exacerbate the vibration. For example, straight square poles are more prone to first mode vibration, while straight round poles are more affected by second mode vibration. Understanding these factors is essential for designing light poles that can withstand wind-induced vibrations and maintain their structural integrity.

Light Pole Wind Induced Vibration Relevant Definitions

First Mode Vibration (Harmonic)

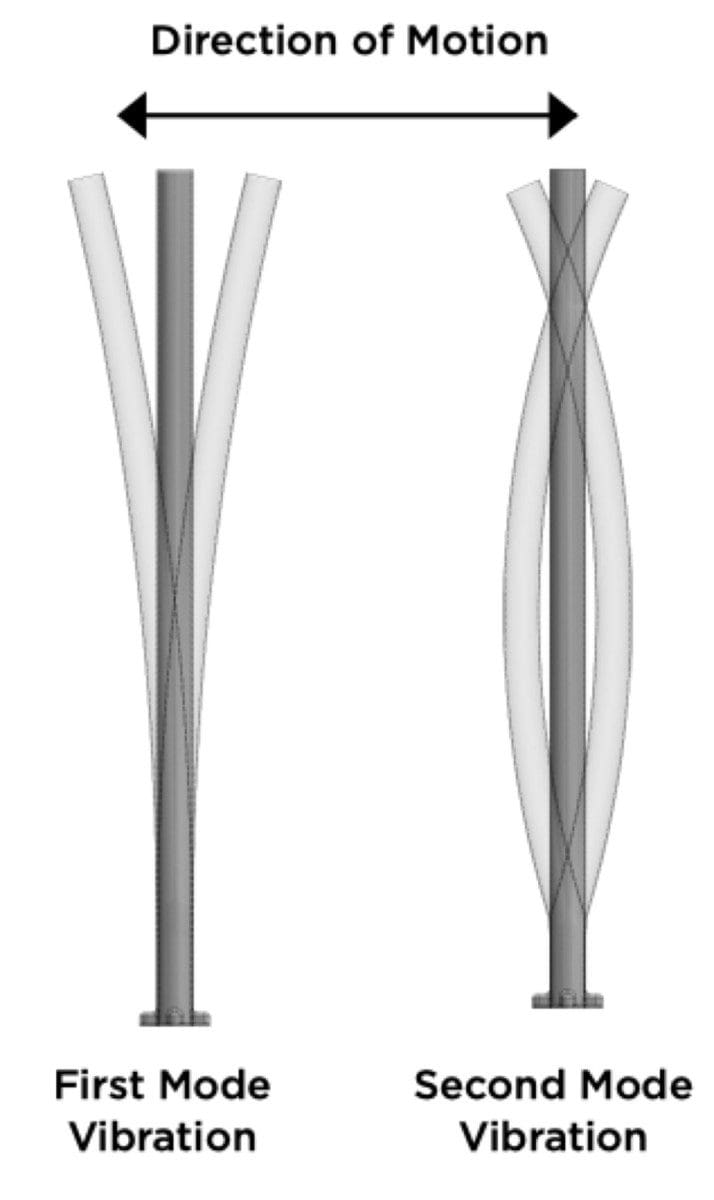

First-mode vibration, also known as harmonic vibration, is characterized by the side-to-side motion of a pole and is typically referred to as “sway”. High velocity gusts of wind cause the greatest displacement at the top of the pole moving at a frequency of about 1 cycle per second. Maximum deflection occurs at the top of the pole during first mode vibration, which is generally not harmful to the pole or luminaire.

Second Mode Vibration (Resonance)

Second mode vibration, also known as resonance vibration, is characterized by the symmetric oscillation that occurs when the wind synchronizes with the pole’s natural frequency. Second-mode vibration occurs near the midpoint of the pole and can cause material fatigue related to pole failure. The typical frequency of movement is about 3 to 6 cycles per second.

Vortex Shedding

Vortex Shedding occurs when second mode vibration matches the natural frequency of the pole. This is caused by a steady, low speed wind moving perpendicular across the pole creating alternating low-pressure vortices on the downwind side of the pole. Vortex shedding frequency can synchronize with the natural vibration frequency of the pole, leading to potential structural failure due to resonance.

Effective Projected Area (EPA)

EPA is a coefficient used by the lighting industry to determine how much force a luminaire will apply to the mounting brackets or pole at a given wind velocity. This value is used in combination with a luminaire’s weight to determine the mounting requirements for a particular application. To determine the EPA of a luminaire, the frontal projected area is multiplied by the drag coefficient of the luminaire.

Structural Factors Affecting Light Pole Vibration

Several structural factors can affect light pole vibration. The pole’s geometry, including its height, diameter, and wall thickness, can influence its vibration. Taller poles with thinner walls are generally more flexible and thus more susceptible to wind-induced vibrations. The type of material used for the pole, such as steel or aluminum, can also impact its vibration. Steel poles, being stronger, may resist vibration better than aluminum poles. Furthermore, the pole’s installation method, including the type of foundation and anchorage, can also affect its vibration. A well-anchored pole with a robust foundation is less likely to experience significant vibrations.

The surrounding environment can also play a significant role in light pole vibration. Nearby structures, obstacles, or terrain features can disrupt airflow, leading to increased wind speeds and turbulence. This can, in turn, exacerbate the pole’s vibration. For instance, poles installed in open landscapes or near tall buildings may experience more intense vibrations due to altered wind patterns.

In addition, the pole’s appendages, such as luminaires, antennas, or other attachments, can also affect its vibration. The weight, size, and location of these appendages can alter the pole’s center of gravity, leading to increased vibration. For example, a heavy luminaire mounted at the top of a tall pole can increase the pole’s susceptibility to wind-induced oscillations.

Understanding these structural factors is essential to designing and installing light poles that can withstand wind-induced vibration. By considering these factors, engineers and designers can develop strategies to mitigate vibration and ensure the structural integrity of the pole. This includes selecting appropriate materials, optimizing pole geometry, and implementing effective installation methods to minimize the impact of wind-induced vibrations.

Light Pole Design Considerations

When selecting a pole consider these design attributes to reduce the risk on wind induced vibration.

- Height – Pole deflection increases as the height of the pole increases causing greater risk of wind induced vibration.

- Wall Thickness – The gauge (thickness) of material affects the rigidity and flexibility of the pole. The higher the gauge the less risk for wind induced vibration because of the reduced flexibility and increased rigidity.

- Material – Poles are available in many different types of material. The most common include steel, aluminum, fiberglass, concrete, and wood. Steel and aluminum are the most common materials used for light poles, with steel having more strength than aluminum.

- EPA Values/ Loading – Overloading and light-loading a pole can greatly affect its performance. The risk of pole failure greatly increases if the EPA value of the luminaire and bracketry exceeds the EPA rating on the pole. Poles with a height greater than or equal to 25 feet loaded with less than 2.0 EPA increase the risk of destructive vibration. Poles are designed to carry a load and should not be installed before the luminaire is mounted.

- Shape – Aerodynamics also affect pole performance. Straight square poles are more often affected by first mode vibration. Straight round poles are more often affected by second mode vibration. A tapered pole can positively change the aerodynamic characteristics, reducing the risk of destructive vibration. Vibration Tendency from highest to lowest is straight square, straight round and round tapered.

Wind Speed is a Key Light Pole Design Consideration

Wind speed can cause light pole vibration. While the pole must be approporately designed to withstand the wind by holding up the weight of the lights, frequently additonal consideration must be made to mitigate light pole vibration. The chart on the right lists the wind speeds that light poles must be able to withstand. Every pole has limits to the wind it can withstand. Click the image on the right to learn more about windspeed and what the wind speed requirements are for your location. Be sure to view the charts in the light pole pdfs to make sure your light poles can handle the light fixture weightm effective projected area (EPA), and widn speed for your location. To discuss this with an Access Fixtures lighting specialist dial 800.468.9925 or click here for a lighting specialist to contact you.

Mitigating Destructive Vibration

A pole damper can reduce the risk of destructive vibration by adding mass. The mass interrupts the natural frequency on the pole. It is recommended that poles over 25 feet, especially square poles, include a vibration damper. Ask your Access Fixtures lighting specialist about pole dampers or contact a local structural engineer to determine if a damper is appropriate for your application.

First Mode Dampers

First mode vibration dampers can be installed to reduce the sway motion of the pole.

Second Mode Dampers

Second mode vibration dampers are used to interrupt the natural frequency of the pole, minimizing the material fatigue caused by the wind.

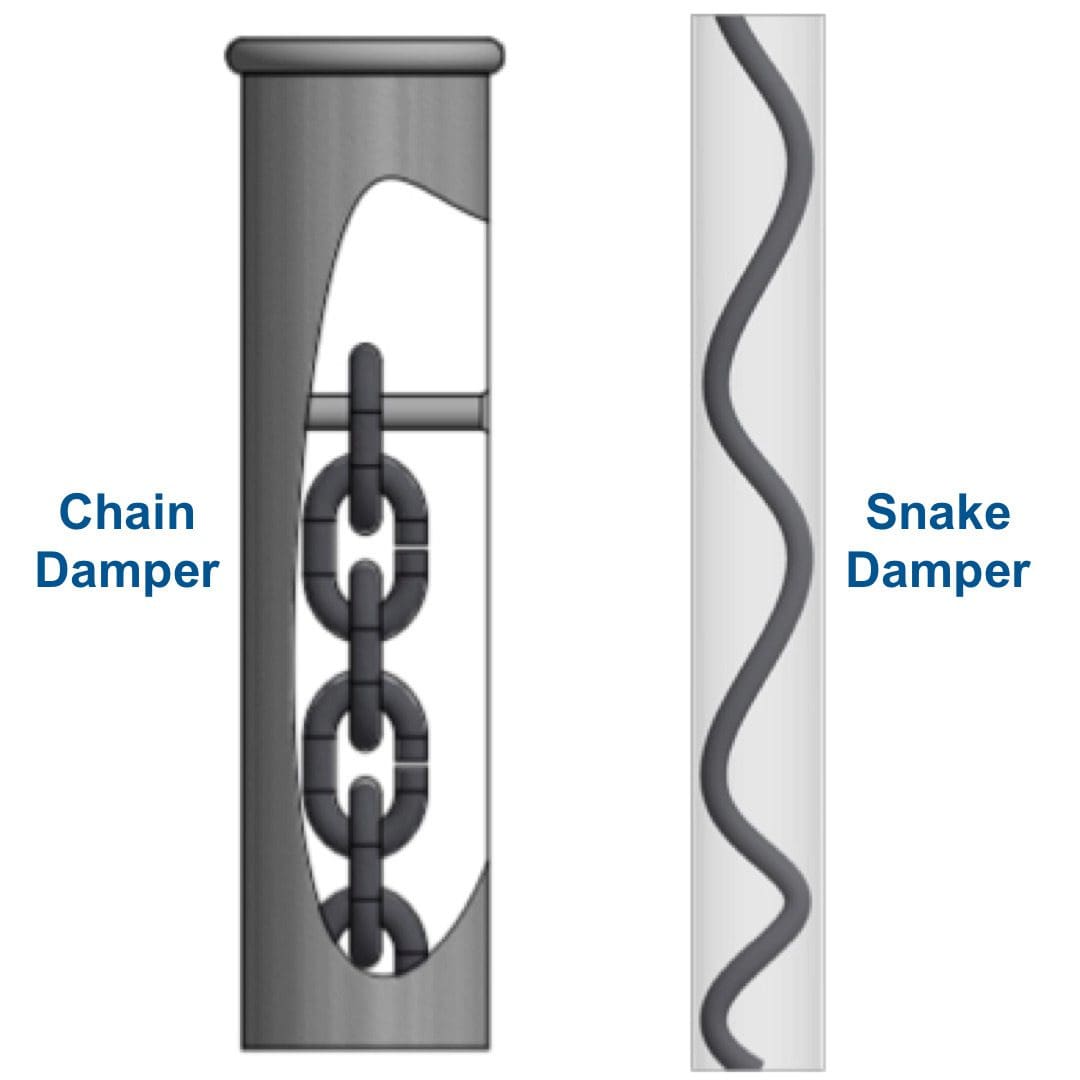

Chain Damper

A chain damper is a factory installed second mode vibration damper that consist of a coated chain hanging from the top of the pole. This disrupts vibration by moving in the opposite direction of the shaft. The chains may create some noise as it moves inside the pole.

Snake Damper

A snake damper is another form of a field installed second mode vibration damper that is installed through the hand hole to disrupt vibration of the shaft.

Some Locations are More Prone to Wind Induced Vibration

Areas with certain environmental variables, such as constant low, steady wind, flat open terrain, large open landscape, and buildings affect the of the pole. Even if you check the special wind regions on a wind speed map, you may need to add strength and or some method of dampening to the poles.

- Open Landscape – Flat areas with limited or no wind obstructive structures. (i.e. large fields, large open parking lots, open roadways).

- Cities / Mountains – Areas with wind altering structures or consistent wind currents. (i.e. skyscrapers, trees, hills).

- Airports – Flat areas with turbulent air from aircraft and no wind altering structures.

- Top of Parking Decks, Bridges – Flat, open areas of elevated structures.

- Local Conditions- Unique site related conditions.

Consult with your local code department for local wind speed requirements and to determine locations that might have added wind issues.

Light Pole Inspection and Maintenance

Pole inspection and maintenance are very important to the longevity of the pole. It is imperative that destructive pole vibration be minimized in a timely manner before structural damage can occur. Inspections should be performed on a regular basis, beginning when the pole is installed and then after one week, one month, six months and annually.

Pole inspections should also be performed after major wind events, as well as when environmental changes to the location could alter wind patterns – i.e. new construction, removal of buildings, or modification to landscaping. If any changes exist, a pole can be compromised in a short period of time, which can result in pole failure. Indications of pole vibration can be observed with the below guidelines:

- Visually inspect for signs of corrosion directly above the baseplate weld and around the hand hole. Corrosion and hairline cracks in the finish may suggest material fatigue.

- During windy conditions, observe the top of pole for excessive deflection and look for rapid oscillation at the middle of the pole. In addition, listen to hear if wires inside the pole are banging against the sides.

- Check the torque values of the anchor bolts. Low torque values could indicate vibration.

- Loosening of threaded attachments, fasteners of the luminaire and missing pole caps.

If signs of pole fatigue exist, a structural engineer should be consulted. The affected pole should be dismantled, and a complete site inspection should be performed. If vibration is, or has, occurred but the pole is still deemed structurally sound, mitigation steps including adding a damper should be performed. If vibration is still present after mitigation, an alternate pole shape should be considered.

Light Pole Vibration Summary

Many factors need to align to create wind induced pole vibration and may be isolated to one location on the site.

Some factors include:

- Project is in a wide-open area.

- Pole is greater than or equal to 25’ and a load of less than a 2.0 EPA • Pole shape, square being the most susceptible to pole vibration.

- If vibration has been an issue in the past in that area.

If these any of these factors are present, it is recommended that a pole damper be installed to reduce the risk of pole failure due to wind induced pole vibration.

Light Pole Warranties

Pole fatigue, damage or failure caused by or resulting from induced vibration, harmonic vibration or resonance associated with the movement of air currents around the product or by any other local condition are specifically excluded from Access Fixtures’ warranty.

More Light Pole Resources

Download Wind Speed Map for ASCE 7-10.

Learn more about High Mast Light Poles.

Learn more about Mid-Hinge Light Poles.

Learn more about Aluminum Light Poles.

Learn more about Steel Light Poles.

Conclusion

Understanding and addressing the risks associated with wind-induced light pole vibration is crucial for the longevity and safety of lighting installations. With appropriate design considerations such as material selection, pole height, wall thickness, and the addition of dampers, the adverse effects of vibrations can be minimized effectively. Regular inspections and maintenance ensure that these structures remain safe and functional, safeguarding against potential failures. By taking these steps, stakeholders can mitigate risks and enhance the durability of their lighting solutions.

Frequently Asked Questions

What is light pole vibration?

Light pole vibration refers to the oscillation or swaying of light poles, typically caused by wind. This can occur in two main modes: first mode (harmonic vibration) which affects the top of the pole, and second mode (resonance vibration) which occurs near the pole’s midpoint.

What causes light pole vibration?

The primary cause of light pole vibration is wind. Specific factors like pole height, material, and shape, as well as environmental conditions such as consistent wind patterns or open landscapes, can exacerbate the effect.

How can light pole vibration be mitigated?

Mitigating light pole vibration involves selecting the right pole attributes, such as material, height, and wall thickness, and installing dampers like chain dampers or snake dampers. Regular maintenance and inspections are also vital to ensure pole integrity.

What are the signs of light pole vibration?

Signs include visible corrosion or cracks, excessive pole deflection, rapid oscillation, and unusual noises during windy conditions. Regular inspection can identify these signs early.

Who should I contact if I suspect light pole vibration issues?

If signs of vibration are evident, it is recommended to consult a structural engineer and perform a thorough site inspection to decide on necessary mitigation steps or replacements.