Stainless Steel Bollard – Commercial LED Stainless Steel Bollards

Stainless Steel LED Bollard Lights

Access Fixtures’ stainless steel LED bollard lights are perfect when only extraordinary appearance and performance will do. Used for illuminating walkways and entrances, stainless steel LED bollards are the ultimate design solution—and they’re practical, too. Stainless steel bollard lights provide illumination for safe egress, offer enhanced security, and are manufactured with 316 stainless steel. The stainless steel bollard light heads are affixed to the body of the bollard light with vandal-resistant screws. Because the screws are located on the sides of the bollard lights, water cannot corrode or pool around them; this design also prevents water from penetrating the bollard.

A gasket between the bollard head and housing acts as another barrier against moisture. Stainless steel LED bollards from Access Fixtures use strong, cast-aluminum mounting plates; the bollards are secured to the base plates with vandal-resistant set screws. These plates are anchored with steel bolts that are sunk into cement.

Stainless Steel LED Bollard Lights—Assembled in the USA

Access Fixtures stainless steel LED bollard lights are assembled in the USA using premium-quality components, including formed 316 stainless steel housings, polycarbonate lenses, rubber gaskets, and cast-aluminum mounting plates. They are available with multiple Kelvins and Amber 590 nm. Access Fixtures stainless steel bollard lights are CSA-rated for wet locations.

Key Takeaways

-

-

Robust Material and Construction: Access Fixtures’ stainless steel LED bollard lights are built with 316 stainless steel, offering exceptional durability and resistance to corrosion, making them suitable for harsh environmental conditions including marine settings.

-

Optics and Design Versatility: These bollard lights come with various optic options like louvers, cone reflectors, and opal lenses to meet different lighting and aesthetic requirements. This flexibility allows for tailored lighting solutions that enhance both functionality and design of outdoor spaces.

-

Efficient and Cost-Effective Operation: The lights are not only designed to be energy efficient but also cost-effective to operate. They can replace traditional lighting systems with significantly lower energy usage and reduced operating costs, supported by photometric studies to ensure optimal light distribution and compliance with specific lighting requirements.

-

Bollard Lights Manufactured with Type 316 Stainless Steel

Stainless steel is the accepted term for any iron-based alloy that contains at least 10.5% chromium. Chromium is used as a corrosion-resistant coating on metal surfaces such as that of a chrome-plated automobile bumper. Chromium is added during the melting stages of the steel, thus forming a homogeneous mixture with the iron and other alloying elements like nickel and molybdenum. This process greatly enhances the metal’s resistance to corrosion.

Type 316 stainless steel is an austenitic chromium nickel stainless steel containing molybdenum. To be considered Grade 316 (UNS S31600), the steel must have at least 2% molybdenum. This composition significantly increases the metal’s resistance to corrosion caused by sulfuric, hydrochloric, acetic, formic, and tartaric acids; acid sulfates; alkaline chlorides; high salinity; and chloride ion solutions. These properties make 316 stainless steel suitable for architectural applications in severe settings, from polluted marine environments to areas with subzero temperatures.

The Specialty Steel Industry of North America (SSINA) and the International Molybdenum Association (IMOA) have produced an excellent designer handbook to acquaint the readers with 300-series stainless steels. The guide details Grade 316—used in Access Fixtures bollard lights—and its performance in areas where coastal or salt corrosion is a factor. Click here to learn about Marine-Grade Finish LED Bollard Lights.

Stainless Steel LED Bollard Light Maintenance

Depending on the intensity of salt and/or air pollutants, stainless steel bollard lights may require light maintenance if you want them to remain in close-to-pristine condition. Even stainless steel tends to get dirty or black and may need to be cleaned. When placed outdoors for an extended period of time, stainless steel can discolor or seem to develop rust, due to the buildup of hard water and road salt particulates; other contaminants carried in rain can also have a negative effect on the appearance of stainless steel. Natural shifts in coloration may occur with stainless steel bollards if they are not occasionally maintained.

Often, a bit of soap and water will remove the thin layer of hard water, rust, or contaminants. An alternative to soap and water is a quality stainless steel cleaner, which may make the process quicker and easier.

Bar Keepers Friend is an example of a highly recommended, affordable stainless steel cleaner that can be purchased at Home Depot or Amazon. For serious discoloration or contaminant buildup, application with a scrubbing pad can improve the process, but the scrubbing pad should not be abrasive, as this may change the finish.

Zep Stainless Steel Polish is an excellent product that can protect stainless steel from contaminants and discoloration. It can be used on stainless steel bollard lights after they have been cleaned to polish and protect the surface. Be sure read the directions and warnings before using any product on your bollards.

Stainless Steel Light Bollard Optics

Stainless steel bollard lights are available in three different optic options: louvers, cone reflectors, or an opal lens. Which optics should you choose for your location? Optics should be selected based on the application requirements, as optics affect the amount and distribution of the emitted light.

Die-cast Aluminum Louvers

Employing beautiful die-cast aluminum louvers, stainless steel bollard lights with louvers look fantastic during day or night. Bollard lights with louver-controlled light distribution have the most restricted light, which make them perfect for locations with dark sky compliance regulations. Most of the light emitted is aimed down toward the ground.

Opal Polycarbonate Lens

The opal polycarbonate lens softens the light emitted and virtually eliminates glare. This selection changes the aesthetics, as it adds white/opal to the stainless steel bollard light. Based on overall appearance, the die-cast aluminum louvers and specialized cone reflectors are the more popular choice.

Specialized Cone Reflector

Specialized aluminum cone reflectors were engineered to optimize the performance of LEDs. Using an LED array or LED module aimed downward from the head of the bollard, the light is projected down and out. The light is also reflected off the specialized cone reflector.

Stainless Steel Bollard Light Dimensions

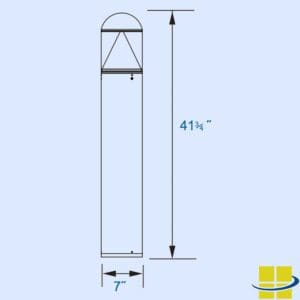

Access Fixtures stainless steel bollard lights are 41.75 tall and have a 7” diameter. Upon request, any bollard can be cut down to a custom height as low as 24″.

LED Bollard Lights Outperform 100w PSMH Bollard Lights

Today, a 15w LED stainless steel bollard light can emit 90% of the light of a 100w pulse start metal halide (PSMH) bollard light and reduce energy use by 87%. View the comparison here.

Stainless Steel LED Bollard Light Efficacy

The specifications of your stainless steel bollard light should be based on what is important to you and/or your customer. Are you hoping to maximize light or efficiency? Is there a specific type of optic you want to use to achieve a certain aesthetic? The PDFs below are sorted so you can quickly and easily meet your objectives. (Please note that not all bollard lights listed in the charts are available in stainless steel. Speak to an Access Fixtures lighting specialist for availability.)

Spacing for Stainless Steel Bollard Lights

Many variables affect how much space you should keep between your stainless steel bollard lights. These variables include the function of the area being illuminated, other light sources in the area, the optics of the bollard lights, the lumens emitted by the bollard, and client preference.

IESNA Footcandle Standards

IESNA set footcandle standards that list the minimum light required for almost any application. The table below lists standards for applications for which bollard lights would be appropriate.

Available Light Sources

Are existing light sources already providing some light in the area? If the existing light is sufficient, certain bollard lights may help add architectural interest or ambiance. If the lighting doesn’t meet IESNA standards, bollard lights can be an effective way to provide additional light.

Preferences

One of our previous customers was an architect who had his mind set on using bollard lights with louvers. He could have met the IESNA standard with fewer cone reflector bollards, but some additional louvered bollards achieved the necessary light levels while satisfying his aesthetic goals. Access Fixtures lighting specialists are available to discuss your objectives. To speak with a lighting specialist, call (800) 468-9925. Click here to learn more about bollard light spacing.

Annual Operating Cost of a Stainless Steel LED Bollard Light

The main annual operating expense of a bollard light is electricity. So, how do you calculate the cost of electricity?

First, find out your cost of electricity per kilowatt hour (kWh). Get your electric bill, take the total cost of electricity and divide it by the kWh. This will make sure you include all aspects of what you are charged, including the customer charge, distribution charge, transition charge, energy-efficiency charge, renewable energy charge, basic service charge, peak demand charge, and sales tax.

Using the Annual Cost per Watt Chart and your cost per kWh, you can calculate the cost of each watt of energy per year. Next, multiply that result by the number of watts used by the stainless steel bollard light. For more detailed instructions on how to calculate the annual cost of electricity to operate a luminaire, click here.

Stainless Steel LED Bollard Lights and Voltage

US residences typically use 120 volts, while Caribbean residences use 120v or 240v depending on the island. Commercial facilities use voltage that varies between 120v and 480v; many sites will use multiple voltages, so property managers need to know the voltage where the bollard lights will be installed. While many stainless steel bollard lights have ballasts or drivers that can handle multiple voltages, it is best to know the voltage before ordering to make sure the bollard lights you order will work with your line.

Stainless Steel Bollard LED Light Installation Instructions

Bollard lights use line voltage and installation must be completed by a licensed contractor or electrician and in accordance with local codes and ordinances, including but not limited to the National Electrical Code (NEC). If you are a licensed electrician or just want to know how bollard lights are installed, the bollard light installation guide for Access Fixtures bollard lights is for you.

When installing bollard lights, make sure the bollard light base plate is level. Access Fixtures bollard light bases come with a built-in level, which makes installation easy; the result, however, will be determined by the quality of the work of the installer.

Replacing Old Bollard Lights Without Pouring New Cement

You can sometimes replace old bollard lights without having to pour new cement. To install new bollard lights without pouring new cement, use mechanical anchors. Access Fixtures bollard lights use 3/8″ diameter bolts. Just select the best bolt length for your installation. Red Head and Simpson Strong-Tie mechanical anchors are reliable options.

Conclusion

In conclusion, Access Fixtures’ stainless steel LED bollard lights represent a fusion of exceptional design and practical functionality, making them an ideal choice for enhancing outdoor environments. These bollard lights not only provide robust illumination for safe egress and heightened security but also feature an impressive aesthetic appeal with their durable 316 stainless steel construction. Equipped with various optical options and assembled with precision in the USA, these lights offer customizable solutions to meet specific lighting needs. Whether you are looking to comply with dark sky regulations or add a stylish touch to architectural projects, stainless steel LED bollard lights from Access Fixtures deliver performance, durability, and style.

Speak to an Access Fixtures Lighting Specialist about Choosing the Right Fixture

Access Fixtures is your factory-direct source for all light fixtures needed to suitably illuminate your property. If you have a lighting question, we will be glad to answer your questions. We want to make sure you get the exact fixture for your needs, your budget, and your goals. We are passionate about lighting and love what we do—we’ll get you an answer. To speak with an Access Fixtures lighting specialist, call (800) 468-9925. Click here for more information on Commercial-Grade LED Bollard Lights.

Frequently Asked Questions on Stainless Steel LED Bollard Lights

What makes stainless steel LED bollard lights resistant to harsh environments? Stainless steel LED bollard lights are crafted from Type 316 stainless steel, which contains molybdenum. This composition significantly enhances their resistance to various forms of corrosion, making them ideal for challenging environments like coastal areas or regions with high salinity.

Can I install stainless steel LED bollard lights myself? Installation of stainless steel LED bollard lights requires a licensed contractor or electrician to comply with local codes and the National Electrical Code. These fixtures use line voltage, and proper installation ensures safety and optimal performance.

How do I maintain my stainless steel LED bollard lights? Maintenance typically involves regular cleaning to remove contaminants such as hard water or road salt. For surface cleaning, mild soap and water or a recommended stainless steel cleaner like Bar Keepers Friend can be used to maintain the pristine condition of the bollard lights.

What are the available optical options for stainless steel LED bollard lights? There are three optical options: louvers, specialized cone reflectors, and opal polycarbonate lenses. Louvers offer controlled, downward-focused light, ideal for dark sky compliance, while cone reflectors optimize light performance and the opal lens softens and distributes light to minimize glare.

How do I choose the right spacing between stainless steel bollard lights? Spacing should be determined based on the function of the illuminated area, other light sources present, chosen optics, and personal preference. Photometric analysis can provide precise guidance on spacing to achieve desired lighting levels and aesthetics.

What are the benefits of using stainless steel for bollard lights? Stainless steel offers superior durability and aesthetic appeal. It resists corrosion, withstands harsh weather conditions, and maintains its appearance over time, making it suitable for both functional and decorative outdoor lighting.

Are stainless steel LED bollard lights environmentally friendly? Yes, these lights utilize LED technology known for its energy efficiency and long lifespan, reducing both energy consumption and the need for frequent replacements, thereby contributing to environmental sustainability.